Careers

THE WORLD IS FACING A HUGE CHALLENGE. BE A PART OF THE SOLUTION.

BECOME AN ENERGY PROBLEM SOLVER.

Head of Plant Engineering

Requirements:

-Successfully completed studies in mechanical or process engineering or training as a design engineer

-Experienced with CAD programs (desirable: AutoCAD Plant 3D and Inventor)

-CAD-supported new design, modification and further development of systems and system components

-Design of frames and suspensions of components

-Creation of layout plans and assembly drawings

-Planning, implementation and documentation of projects in the field of plant construction

-Monitoring and adherence to specifications regarding costs, deadlines and quality

-Interface coordination between external service providers and the project manager

Purchasing Manager

Requirements:

-Several years of professional experience in purchasing, ideally in plant engineering or a related industry

-Experience in contract negotiations and supplier management

-Developing and implementing a purchasing strategy that supports the business objectives

-Identifying and qualifying suppliers and negotiating contracts and conditions

-Ensuring the availability of materials and components for production

-Budget responsibility and cost control in the purchasing area

-Collaborating with other departments to ensure product quality and delivery times

Head of Industry Automation

Requirements:

-Degree in automation technology or equivalent

-Min 5 years of experience in the development and implementation of PLC system controls in the process industry

-Experience in full automation of process plants

-Knowledge of IP-based network technology

-Knowledge of programming fail-safe control systems

-Planning and implementation of process controls

-Design of control hardware

-Programming of PLC and visualization systems

-Creation of step chains for fully automatic operation

-Execution of remote maintenance

-Control system support during the commissioning of process plants

Head of Technology in the field of synthetic fuels

Requirements:

-Degree in the field of process, plant, environmental or chemical engineering or a comparable qualification

-Min 3 years of professional experience in plant engineering and process engineering projects, ideally with a background in synthetic fuel technologies

-Good knowledge in the fields of thermodynamics, fluid mechanics and heat and mass transfer

-Preferably have knowledge in system integration and/or process simulation

-Content-related and topic-related contact for all technological questions concerning synthetic fuel production

-Project planning, design and simulation of process and solution concepts

-Process engineering design, specification and selection of safety equipment, apparatus and machinery according to international guidelines and regulations

-Plant scaling and support in scale-up processes of process plants

-Bundling of cross-departmental and cross-team competencies

Process Engineering Technician

Requirements:

-Background experience as a technician, preferably in the field of plant engineering or process engineering

-Min 3 years of relevant professional experience

-Skilled in reading technical drawings

-Assembly of process plants

-Ensuring compliance with production specifications

-Supervision and organization of work with external companies

-Optimizing, integrating and designing process flows

-Carrying out quality tests on assemblies and entire plants

-High motivation and ability to work in a team

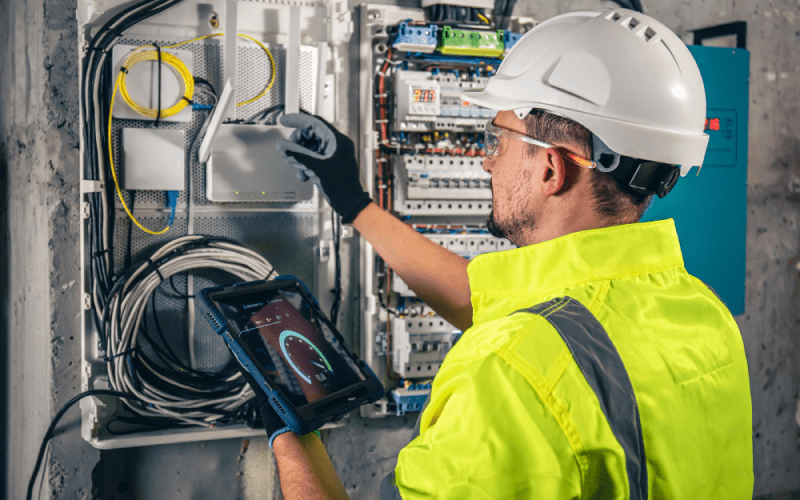

Electrical Engineer

Requirements:

-Master craftsman/technician in electrical engineering or completed studies in electrical engineering or a similar field

-At least 2 years of professional experience in the field of electrical engineering, ideally in refinery plant construction

-Precise and structured way of working

Plant Operators

Requirements:

-Min 3 years of related experience required

-Independent monitoring and operation of the plant

-Operation and technical support

-Organization of rebuild and optimization measures

-Pre- and post-processing including evaluation of results

-Ensuring trouble-free operation and the quality of the synthetic fuels produced

-Independent detection and, if necessary, elimination of malfunctions and minor defects and reporting them to the responsible person(s)

-Implementation and continuous further development of the repair of our innovative plants

-Support during the commissioning of the process plants

-Monitoring and compliance with safety measures

-Evaluation of process data and preparation of operating documents

-Willingness to relocate for work at different innovative plants commissioned

We are a performance-driven company

As a performance-driven company, we prioritize results. Our dedicated team, innovative approach, and unwavering commitment ensure superior outcomes. Choose us for excellence, efficiency, and a track record of delivering success in every aspect of our operations.

- Accountability

- Citizenship

- Excellence

- Integrity

- Safety

- Enthusiastic

- MOBILITY

The working container is all set up where there’s no required rough-in uplity work, different from fixed

facility structures. Any renovation required when installing or relocating would more cost and

production startup downtime.

- SCALABILITY

The standard production capacity of each HRF-2000 system in a 40 feet container is 2.5MT per hour

when operating. When operations demand more production capacity, additional units can be installed

alongside or stacked on top one another.

(For clients interested in our HRF-2000 technology requiring substantial production capacity, we can

custom tailor different commercially viable solutions in a non-containerized framework.)